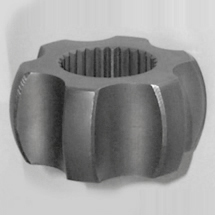

Constant velocity joints are used in automobiles to transfer power between the engine and the tires, and function much like the neck or hip joints do in a human body—constantly changing angle in response to the road surface. These components are also rotating under tremendous force during vehicle operation, and are as critical as the brakes or suspension. Because FF cars drive the front wheels,this type of automobile would not be able to function without a constant velocity joint. At AIKOKU ALPHA, we make the inner races that go inside these constant velocity joints. These components require an extremely high degree of precision and quality, and we proudly manufacture 20% of the world’s supply.

CV joint using an inner race from AIKOKU ALPHA

Products

- VL and UF products

-

・Cold forming makes it possible to eliminate the grinding process for ball grooves (near net shape)

・We aim for ideal form in the axial direction of the ball groove shape

VL

| Anti-abrasion section | Ball groove |

|---|---|

| Ball groove variation |

Ball groove shape: 20 μm P.C.D ±25μm |

| Grade can be selected by PCD | 10-μm increments |

UF

| Anti-abrasion section | Ball groove |

|---|---|

| Ball groove variation |

Ball groove shape: 20 μm P.C.D ±10μm |

| Grade can be selected by PCD | 10-μm increments |

- BJ and DOJ products

-

・Near-net shape minimizes ball groove grinding margin

・Quality is guaranteed through an integrated manufacturing process that goes from cold forming to precision machining and then to heat treatment

BJ

| Ball groove | Overall grinding margin: 0.15–0.3 mm |

|---|---|

| Size (maximum) | φ80 mm (outer diameter) × 40 mm (height) |

DOJ

| Anti-abrasion section | Ball groove |

|---|---|

| Ball groove variation |

Ball groove shape: 30 μm P.C.D ±30μm |